Profile of a 7-Digit Mismatched Serial Number Error

Bob Liddell is among the foremost if not the foremost U.S. small size error collector. He is always looking for new types of misprints. The modern generations of 32-subject COPE…

Bob Liddell is among the foremost if not the foremost U.S. small size error collector. He is always looking for new types of misprints.

The modern generations of 32-subject COPE and now 50-subject LEPE numbering press have been a boon, because they are cranking out error types never seen before. Lately some previously unheard-of 7- digit mismatches have burst onto the scene. Of course, Bob had to get examples.

The purpose of this article is to profile one of the newly recognized 7-digit mismatch varieties. The thing that makes this numbering error so unusual is that when it occurred, all 8 number wheels were turning in lockstep with each other within one numbering head each time a sheet passed through the press. We have never seen this before.

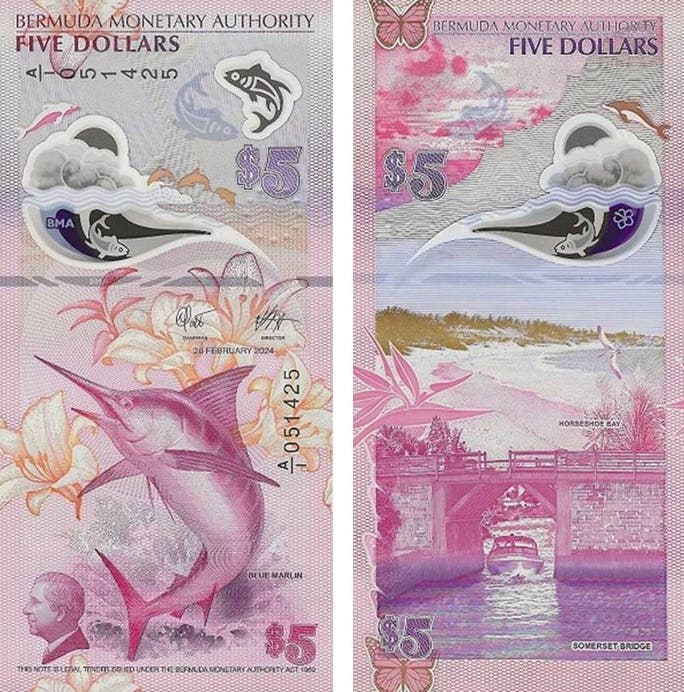

Pictured here are two notes from the same pack from this error run. The serials differ by 32 sheets. The error occurred in a 32-subject COPE numbering press.

The first of these two notes that crossed an auction block really tickled me. The left serial was so off the wall, I figured the press operator simply failed to set the beginning number. But, when Bob sent a scan of the second note, I was astonished. Yes, the last two digits in the left serials differed by 32 as expected but the first 6 digits made no sense at all. My expectation was that the left six digits would be identical on the two.

I filed the scans with the intent to return to them after I got past a couple of writing deadlines. I pulled them up a week ago to determine if I could detect a pattern.

Suddenly it hit me. Each of the 8 digits in the left serials on the notes was off by 2. The right serials were 32 apart so it was obvious that as the right serials progressed normally, every digit in the left serial was turning in lock step! Never saw that before, in fact, never even imagined that such a thing could happen.

Feeling quite pleased with the finding, I shot off an email to both Liddell and serial number guru Derek Moffitt pointing out the systematics of the mismatch. I was wondering how many thousands of this particular error might have been made and why we haven’t seen more from the same run?

Moffitt immediately fired back. “So, counting backward (well, forward!) we can conclude that the two serials would have matched at 06030663, which tells us when something went wrong. Neat!” Hum, why hadn’t I made that leap?

Liddell’s mismatches were from the G4 position on 32-subject sheets numbered on a COPE press. Those presses carry out these functions: (1) print the black Federal Reserve Bank seals and district information, (2) print the green serials numbers and Treasury seals, (3) separated the notes, and (4) band them into packages of 100. Numbering is vertical through the sheets in each of the plate positions. The feed stock for a COPE press consists of two stacks of half sheets because the sheets are cut in half before reaching the press. Two half sheets are simultaneously taken from the tops of the two 16-subject stacks and fed face-up through the respective sides of the press. They are discharged face-up in cut form into 32 bins, one for each plate position.

Numbering progresses from the highest to lowest serial number in each plate position during the press run so that the lowest numbers end up on top in each bin. Yes, the machines number from highest to lowest.

I have arranged the serial numbers in the accompanying table so that the top pair of serial numbers were printed first and the bottom pair last. Consequently, the serial numbers in the right column progress consecutively down the table in decreasing order in as they were numbered. Those on the left also decease downward, but every number wheel turned one digit with each pass of the half sheets through the press.

I have no idea what allowed the number wheels to lock up causing them to rotated together. The strange pairs of little green squares to the left of the left serial numbers were printed from part of the numbering head that somehow was forced upward in order to get inked. Undoubtedly, those squares are part of the mechanism that failed.

Clearly, these mismatches were not caused by operator error. Their cause was entirely mechanical.

Both of the notes illustrated are lightly used, revealing that they were not from a pack found by some fortunately bank teller that will be leaked slowly onto the market. Rather, they probably were retrieved shortly after being released into circulation. If others do turn up, we’ll have to see if they fit into the series presented on the table.

Open ended is how long the problem persisted. This is a glitch that couldn’t self-correct so the rest of the press run should have been affected provided the operator didn’t spot the problem, shut off the press and correct it.

After leaving the machine, the notes, which already are banded into 100-note packs, pass through one final but cursory inspection where an operative flips through the ends of the pack looking for obvious flaws. If something is found, even if it occurs on only one note, the entire pack is rejected and replaced with a pack of star notes. Beyond that, the packs are assembled into units of 800 notes that are shrink wrapped in plastic and then assembled into 4,000-note bricks that are banded and wrapped in kraft paper.

What amazes me about serial numbering is the complexity of the machines. The COPEs have 64 serial number registers; the new LEPE presses have 100. They are mounted on rotary drums the size of car engines and the operator has to set every numbering register just right. I find it remarkable how few mismatches make it out considering the thousands of press runs per year that are executed.